We held a talk session with four guest participants of the project at the <RW with WORKERS 100 PJ> kick-off event, which took place on Sunday, December 15, 2024. We listened to their thoughts on their activities, passion for craftsmanship, and motivations for participating in the REKROW project. They shared insights into their current endeavors and future aspirations.

The first talk featured Mizuki Tachikami from Spingle Company, the brand behind “SPINGLE.” He shared insights into SPINGLE’s approach to craftsmanship, the product development done with REKROW, and discussed the REKROW project’s past and future.

Project Members TALKS Guest:

Mizuki Tachikami, Spingle Company

Spingle Company started in 1997. It is a subsidiary of Nichiman, a rubber processing company that was founded in 1933, and was initially focused on manufacturing rubber boots and casual shoes. Though it’s been over 90 years, the company realized the importance of having items that clearly identify their brand, items that people could immediately recognize as theirs. This led to the creation of SPINGLE MOVE (now known as “SPINGLE”). Since its launch in 2002, the brand has continued for 20 years. SPINGLE shoes are available in unisex, women’s, and business styles, and the unisex line has remained a long-life design since the brand’s inception. Particularly in Europe and the U.S., products with consistent design are highly appreciated, and this is something the company is eager to nurture.

SPINGLE × RW Collaborative Product

The conversation about collaborative products began around the time RW was just being formed. In the early days of RW, there was a vision to turn the workwear collected from participants into products for their families. This concept expanded into the goal of promoting local craftsmanship to a wider audience. The project developed products for employees, and these items made from repurposed workwear were handed out.

RW has been collecting workwear piece by piece, unmaking it by hand, turning it into fabric, and then creating products. The colors that emerge from the deconstructed fabric are all different, which adds an interesting element to the shoes, as each one has a unique expression. Typically, shoes are made as a matching pair, but with this collaboration, it was refreshing to allow for differences between the left and right shoes. As the fabric was patchworked, we paid attention to ensure the seams didn’t overlap, and since the material was indigo, we took care to avoid color transfer to the rubber parts. After overcoming all these challenges, the product was completed.

SPINGLE’s Craftsmanship

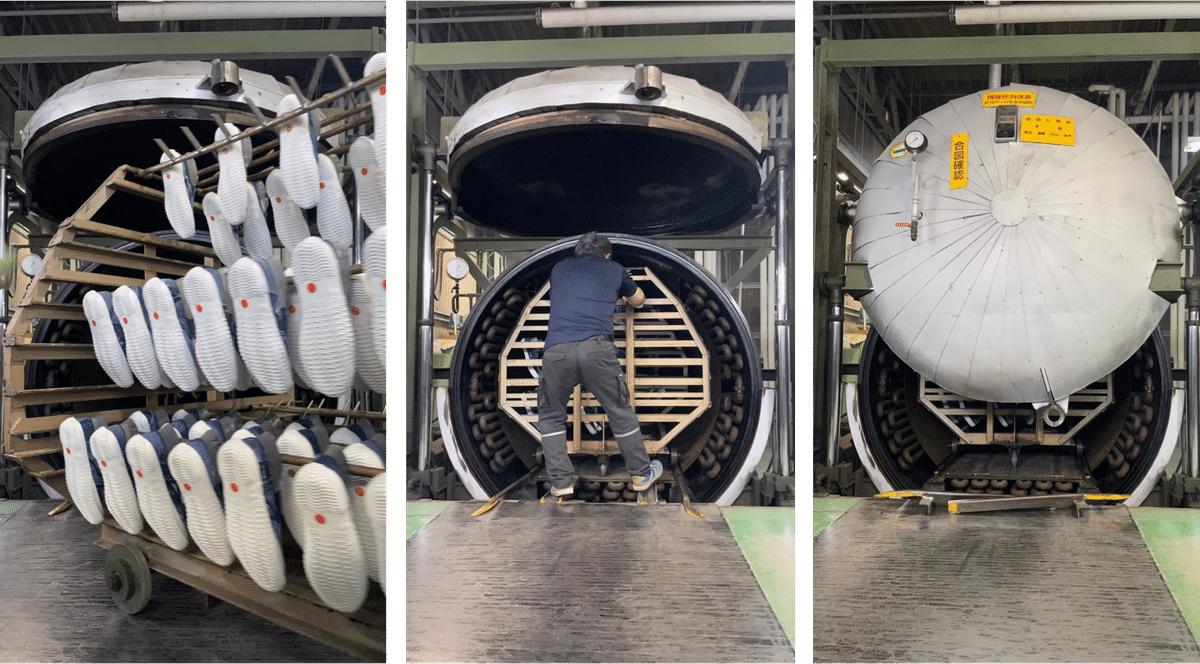

(RW) We, at RW, had the opportunity to visit the factory and experience firsthand the incredible craftsmanship behind each pair of shoes, carefully made by skilled artisans.

(SPINGLE) At Spingle, what we value in our craftsmanship is the rubber itself and the kangaroo leather used for the uppers of the shoes. We focus on using these materials as efficiently as possible, recycling them when necessary. Kangaroo leather can be temperamental and often has scars and wrinkles, so we can’t use those parts for the shoes. But we strive to make the most of what we have. The leftover materials are also repurposed into novelty products, which is part of our responsibility as a manufacturer.

In addition to creating shoes that are comfortable to wear, we also aim to make shoes that will last a long time. Our company has a repair division that mainly handles sole repairs. At the same time, we can repurpose the leftover materials from production for repairs, making it a great advantage in using high-quality materials without waste. We are also working on developing materials for the soles of shoes that resist wear, so they last longer. We’re committed to craftsmanship and work seriously on our products.

(RW) Repair is something RW would like to focus more on in the future. Spingle has the RUBEAR CNF sole, which is used for repairs.

Spingle has had a repair division for about 10 years. Recently, the demand for repairs has been increasing. Both the outsole and insole of the shoes can be repaired. Although this service is primarily available in Japan, we also have overseas customers who send shoes to be repaired while they are visiting Japan.

(RW) While leather shoes are often repaired and used for longer, there might still be limited recognition for the habit of repairing sneakers and using them for an extended period.

(SPINGLE) Given that our shoes are made from leather, I’ve heard that some customers have worn them for 10 years after having them repaired. From a business perspective, selling more shoes for more profit is likely the goal, but from the maker’s perspective, there’s nothing more gratifying than knowing that the shoes are still in use after so many years.

(RW) Six people from Spingle will participate in the project. We hope that the workwear, just like our products, becomes something that people can continue to wear for a lifetime, not just 10 years.

SPINGLE

Instagram: @spingle_official

Website: https://www.spingle.jp/

74-1 Fuchu Town, Fuchu City, Hiroshima Prefecture

SPINGLE PV

“Creating Comfortable Time, Starting from the Foot”

Watch on YouTube

RW Note: [REKROW with WORKERS 100 PROJECT] A New Region-Based Project from REKROW!

Read more on note